We all know that large buildings and some large shopping malls require huge amounts of electrical energy, which requires reliable transmission equipment, and bus ducts can solve this problem very well.But in fact, bus ducts also have many different functions and styles. Now Chaoye Electric will introduce to you the different classifications of bus ducts.

According to the purpose, the bus duct generally consists of the starting bus duct, the straight-through bus duct (with jacks and without jacks), L-shaped vertical (horizontal) bent busbar, and Z-shaped vertical (horizontal) offset busbar , T-type vertical (horizontal) tee busbar, X-type vertical (horizontal) four-way busbar, variable capacity bus duct, expansion bus duct, terminal head, terminal junction box, plug-in box, bus duct related accessories and fastening devices composed of etc.

According to the insulation method, it can be divided into three types: air-type plug-in bus duct, densely insulated plug-in bus duct and high-strength plug-in bus duct.

Air-type plug-in bus duct (BMC).Since the joints between the busbars are softly connected with copper sheets, the weather in the south is humid, and oxidation is easy to occur between the joints, resulting in poor contact between the joints and the busbars, making the contacts easy to heat up, so it is rarely used in the south.Moreover, the volume between the joints is too large, the dimensions of the horizontal busbar sections are inconsistent, and the appearance is not beautiful enough.

Compactly insulated plug bus duct (CMC).Its moisture-proof and heat dissipation effects are poor.In terms of moisture resistance, busbars are prone to moisture and water seepage during construction, resulting in a decrease in phase-to-phase insulation resistance.The heat dissipation of the busbar mainly depends on the casing. Due to the compact arrangement and installation between the lines, the heat energy of the L2 and L3 phases dissipates slowly, resulting in a high temperature rise in the busbar trough.The densely insulated plug-in bus duct is limited by the shell plate and can only produce horizontal sections no larger than 3m.Due to the small air gap between the busbar phases, when the busbar passes a large current, a strong electric force is generated, causing the magnetic oscillation frequency to form a superposition state, causing excessive noise.

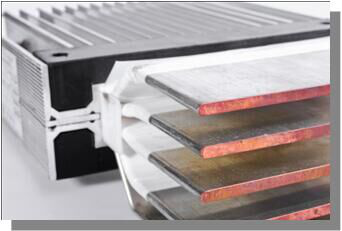

High-strength closed busway (CFW).The manufacturing process is not limited by the plate material. The outer shell is made into a tile groove, which increases the mechanical strength of the busbar. The horizontal section of the busbar can be produced up to 13m long.Because the shell is made in the form of a tile trench, the busbars are intentionally separated and fixed at the trench position. There is a spacing of 18mm between the busbars, and the ventilation between the busbars is good. The moisture-proof and heat dissipation functions of the busbar duct are significantly improved, and it is more suitable for the southern climate; because the busbars are There is a certain gap between them to reduce the temperature rise of the wire, thus improving the overload capacity and reducing the magnetic oscillation noise.However, the stray current and inductive reactance it generates are much larger than those of dense bus ducts. Therefore, when comparing the same specifications, its conductive row cross-section must be larger than that of densely insulated plug-in bus ducts.

The plug-in busway is a tree-trunk system. It has the advantages of small size, compact structure, reliable operation, large transmission current, easy tap feeding, easy maintenance, low energy consumption, and good dynamic and thermal stability. It is widely used in high-rise buildings. widely used.

Release time: 2024-03-04